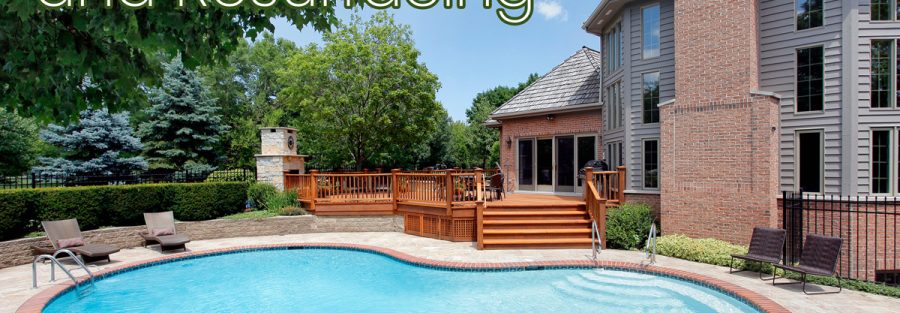

Gel Coat in Pool and Spa Resurfacing

Do you have a swimming pool or spa that needs update and repair?

Great, we can handle. We do pool resurfacing serving all cities in Los Angeles County. We can repair and upgrade the surface of your pool. White or light blue color for your satisfaction.

We use high quality resins, fiberglass mat and gel coats made in USA.

Gel coat is a specialized resin-based material used in the manufacturing of fiberglass reinforced plastic (FRP) products, such as boats, pools, Spas, and RVs. It is typically applied to the mold surface before the fiberglass is laid down, and it serves as a protective outer layer for the finished product.

Gel coat is a thick, viscous liquid that is applied in a thin layer to the pool surface using a roller and brush. Once applied, the gel coat hardens into a smooth, durable surface that is resistant to scratches, fading, and weathering.

Gel coat is available in a range of colors and can be custom tinted to match specific design requirements. For most pools and spas we use white and light blue color It can also be formulated with additives to provide additional properties, such as UV resistance, flame retardancy, or non-slip texture.

Overall, gel coat plays an important role in the manufacturing of FRP products, providing a high-quality finish and protecting the underlying fiberglass from damage and degradation over time.

Give us a call and we can resurface your pool or spa with our gel coatings made in the USA. Please text us some photos and dimensions.

How Gel Coat is Applied!

Gel coat is typically applied to a prepared surface in the following steps:

- The mold surface is cleaned and prepared: The mold surface should be cleaned thoroughly and any imperfections should be sanded or filled. The mold should also be polished to a high gloss to create a smooth, even surface.

- The gel coat is mixed: Gel coat is typically supplied as two separate components, the resin and the hardener, which are mixed together in the correct proportions. The gel coat can also be tinted to the desired color at this stage.

- The gel coat is applied: The gel coat is typically applied using a spray gun, brush or roller. The first layer of gel coat is applied thinly and evenly to the mold surface. It is important to ensure that there are no air bubbles or voids in the gel coat layer.

- The gel coat is allowed to cure: Once the first layer of gel coat has been applied, it is allowed to cure for a set amount of time, usually several hours.

- Additional layers of gel coat are applied: Depending on the desired thickness of the gel coat layer, one or more additional layers of gel coat may be applied, with each layer being allowed to cure before the next is applied.

- The fiberglass is laid down: Once the final layer of gel coat has been applied and cured, the fiberglass is laid down over the gel coat layer and allowed to cure.

- The finished product is removed from the mold: Once the fiberglass has cured, the finished product is removed from the mold, and any excess gel coat is trimmed and sanded away.

Overall, the process of applying gel coat is a critical step in the manufacturing of fiberglass reinforced plastic products, as it helps to create a smooth, durable finish that protects the underlying fiberglass from damage and degradation.